If you have a broken tailgate that has cracked or rusted metal and won’t close or stay shut and stable, this guide and video has some steps you can follow to fix it yourself with new metal and a welder.

How to Fix a Rusted, Cracked and Broken Tailgate That Won’t Close

Steps to fix a rusted, cracked and broken tailgate

- Sand Down the Area

Sand down the broken area on the tailgate that’s full of rust and cracks with a sanding disc and die grinder.

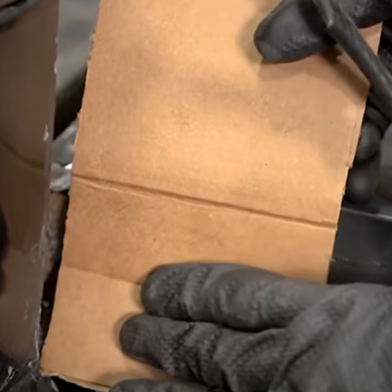

- Gauge How Much Metal You’ll Need with a Piece of Cardboard

Inspect the area and decide where the metal sheet should be placed on the tailgate. In this example, we will be covering rusted metal on the edge of the tailgate, the ridge underneath the rusted area, and up along the ridge. This will add to the strength and structure of the tailgate.

Place a piece of cardboard on the rusted area to get an idea of how much metal you’ll need, and cut it down to size if needed.

- Pick the Right Metal and Cut It to Size

You don’t want small, weak or thin metal that’s flexible and can eventually break. You also don’t want metal that’s too thick, hard and difficult to cut and bend.

In this example, we took metal from an old exhaust pipe. We placed the metal in a vice, cut it down the center with a cut-off wheel, pulled it apart with pliers, and flattened it with a ball-peen hammer.

Once you have the sheet metal ready, place the piece of cardboard on top of it. Trace around the cardboard and cut the metal out with a metal cutter.

Grind any sharp edges down with a sanding disc.

- Mold the Metal to the Right Shape

Place the metal to the broken area on the tailgate and, using a tape measurer or taking a rough estimate, mark on the metal where you will be making any bends, like at the ridge or the lip.

Place the piece of metal in a vice, bend it over with a hammer, and make sure it lines up. If it doesn’t line up, grind parts of it down so it doesn’t hit the body of the truck.

In this example, we spliced the metal and drilled holes into it so the metal can bend and attach to the bent tailgate after being tack welded. The holes cut into the metal are for plug welds, which will add extra stability, structure, and strength.

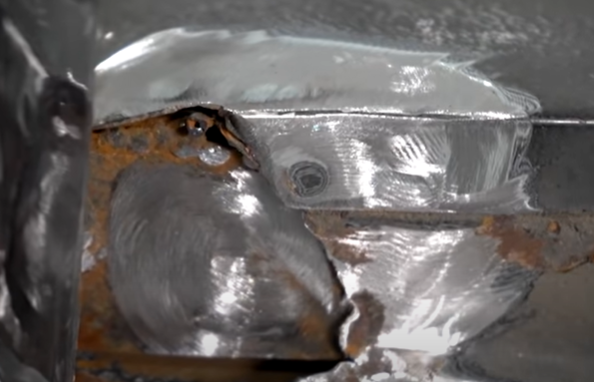

- Weld the Metal to the Tailgate

Wearing the right welding gear, weld the metal to the tailgate. Once the sheet is tacked on, tap it with a hammer to bend it into the shape of the tailgate.

- Test How Well the Tailgate Closes

With the new metal welded on, test how well the tailgate closes, and make sure the tailgate is working to your satisfaction.

- Paint the Welded Area

Once the metal has been welded, paint the area to prevent rust and cracks from forming on the metal. Find a paint that matches your vehicle and place a coat on.

DIY How-to Videos: Learn to Do More than Fix a Broken Tailgate

Find out how to fix more than a broken tailgate with tips and instructions in our how-to videos. We have thousands of videos for repairs on hundreds of makes and models.

Read More Tips

- How to Paint a Plastic Bumper with Spray Cans

- How to Fix Paint Chips on a Car, Truck, or SUV

- Shaking or Pulling Steering Wheel? How to Check the Brake System and for a Seized Brake Caliper

- What Is Fuel Injection? How Does It Work?

- How Distributor Ignition Systems Work

Shop Parts and Tools

- Tailgate Cables

- Tailgate Hinges & Related

- Steering & Suspension

- Tailgate Handle

- Tailgates

- Brakes & Wheel Bearing

- Headlights & Lighting