If you are a member of an automotive forum / message board of any sort, you are no stranger to acronyms, abbreviations, and bizarre automotive lingo. Noob’s are often left overwhelmed and confused for weeks as they are hit with the automotive slang learning curve. Since I too was once an automotive forum newbie, I feel like it is my duty to share some of this slang with the masses. If you are so bold as to become a member of an automotive forum / message board, it will make your experience 10000x more fun and educational. Here we go…….

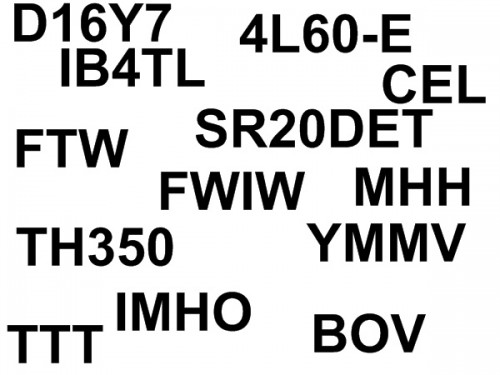

Engine names and sizes – Could be displayed in cubic inches, liters, or factory engine code. Engine code is typically a mix of letters and numbers.

General guidelines: Old cars = use cubic inches, newer non-performance cars = use liters, newer more performance-oriented vehicles = use factory engine codes.

Cubic Inches Examples: 289, 292, 307, 331, 348, 350, 401, 409, 429, 454, 472, 502, 572………etc….

Liters Examples: 1.8L, 2.0L, 2.2L, 2.4L, 3.0L 4.3L, 5.0L, 5.3L, 5.7L, 5.9L, 6.6L, 7.3L…..etc…..

Factory Engine Code Examples: LS1, SR20DET, 4G63, D16Y7, 13B-REW…..etc….

Transmissions – Almost always a combination of letters and numbers.

Examples: TH350, TH400, KM132, T-56, T5, C6, R-154, 4L60-E, 4T45-E

General Chat – These could be used for normal everyday terms

AFAIK – As Far As I Know

BBK – Big Brake Kit

BOV – Blow Off Valve

BRB – Be Right Back

BTDT – Been There Done That

BTW – By The Way

CAI – Cold Air Intake

CEL – Check Engine Light

DBW – Drive By Wire

DIY – Do It Yourself

FAQ – Frequently Asked Questions

FF – For Free

FS – For Sale

FTL – For The Lose

FTW – For The Win

FWIW – For What It’s Worth

GB – Group Buy

HID – High Intensity Discharge (Headlights)

HTH – Hope This Helps

IAC – Idle Air Control

IB4TL – In Before The Lock (When you know the forum moderators are going to lock the thread, you get in fast!)

IIRC – If I Recall Correctly

IMHO – In My Honest/Humble Opinion

ISC – Idle Speed Control

LMM – Losing My Mind

LOL – Laughing Out Loud

MAF – Mass Air Flow Meter

MHH – My Head Hurts

OBO – Or Best Offer

OEM – Original Equipment Manufacturer

ROFL – Rolling On Floor Laughing

TB – Throttle Body

TGFTT – Thank God For This Thread

TIA – Thanks In Advance

TTT – To The Top (Used to move your thread to the top of the page)

WOT – Wide Open Throttle

WUT/WAT/WHUT – What?!

WTB – Want To Buy

WTT – Want To Trade

YMMV – Your Mileage May Vary

YRMV – Your Results May Vary

As I come across more of these, I will add them to this list, so you can always reference it in a time of need. Acronyms FTW!