There are different flares you can make on a brake line, such as the double flare and bubble flare. Knowing how to make a bubble or double flare brake line will help with any of your DIY brake line repairs. This article and video reviews how to make bubble flare and double flare brake lines, and also how to cut and bend brake lines yourself.

How to Flare Brake Lines Yourself

Why Cut, Bend, Flare, and Replace Brake Lines Yourself?

If the brake or clutch lines are rusted or leaking, it’s a good idea to replace them, and it’s usually cheaper to replace them on your own. The steps involve cutting, bending, and flaring the brake lines, and these can be done with a few special tools.

The Difference Between a Single Flare, a Double Flare, and a Bubble Flare

A double flare bends the metal over and in, while a bubble flare bubbles the metal up. These flares add more protection to the brake lines with double the safety and thickness, and will last longer.

A single flare flares the metal out, but it doesn’t bend over. They’ll cause leaks and aren’t safe to use with brake lines.

How Do I Know If I Need a Bubble Flare or Double Flare Brake Line?

Double and bubble flares are the two different kinds of brake lines you want to make when replacing brake lines yourself. The type of brake line you’ll need depends on the type in your car. Some vehicles will need bubble flared brake lines and others will need double flared brake lines. You can tell if your vehicle’s brake lines are double or bubble flared once the brake line is removed and inspected.

Tools Needed

- Tubing bender

- Tubing cutter

- Double flare kit or bubble flare kit (depending on application)

- Fittings (Matching size and thread type)

- Roll of brake line

How to Double Flare Brake Lines

Steps for How to Make a Double Flare Brake Line

- Place the Fitting onto the Brake Line

Place the fitting onto the brake line before flaring the line

- Thread the Brake Line so It Protrudes from the Concaved Threads on the Flare Bar

Notice the concaved area on one side of the flare bar where the threading starts, compared to the backside that is flat. Thread the brake line through the bar so the end that will be flared protrudes from the concaved threads.

- Place an Adaptor next to the Brake Line

Place an adaptor (3/16 inch and 1/4 inch are the most common) onto the flare bar, and thread the brake line so it’s level with the bottom lip on the adaptor. Having the brake line a little over the lip is okay, but you do not want the brake line to be falling below the lip’s height.

- Tighten the Screws on the Flare Bar

Tighten the screws on the flare bar

- Double Check the Alignment of the Brake Line and Adaptor Lip

Double check the measurement of the brake line and lip on the adaptor

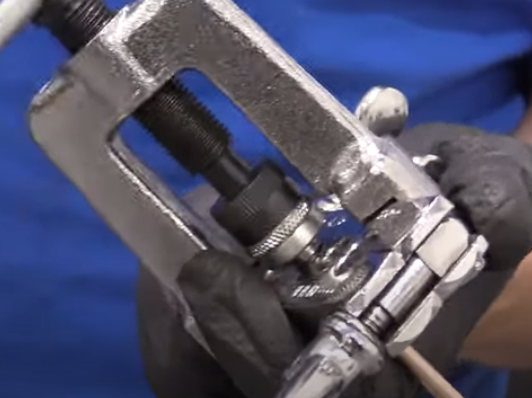

- Place the Adaptor Tool into the Brake Line

Place the adaptor tool into the brake line

- Insert the Yoke Press Tool into the Adaptor and Confirm the Parts Are Aligned

Slide the pressing tool over the adaptor and make sure the adaptor is sitting straight and level and has not fallen to the side or to a crooked position

- Tighten the Yoke Press until the Adaptor Touches the Flare Bar

Tighten the pressing tool until the adaptor bottoms out and touches the flare bar

- Remove the Adaptor

Remove the adaptor from the brake line and pressing tool

- Line the Pressing Tool Up with the Brake Line

Line the pressing tool up with the hole on the brake line

- Tighten the Press into the Brake Line until It Bottoms Out

Tighten the press into the brake line until it feels like it will bottom out

- Remove the Pressing Tool

Once the press is snug, loosen and remove it

- Remove Any Burrs from the Brake Line

Wipe off any burrs with sand paper or a deburring tool. Clean off the brake line once finished

How to Bubble Flare Brake Lines

- Notice the concaved area on one side of the flare bar where the threading starts, compared to the backside that is flat. Thread the brake line through the tool so the end that will be flared is level with the concaved threads

- Tighten the screws on the bar—tightening the side closest to the line first

- Tighten the adaptor to the yoke press tool

- Place the pressing tool into the brake line

- Tighten the pressing tool until it bottoms out

- Loosen and remove the pressing tool

How to Cut and Bend Brake Lines

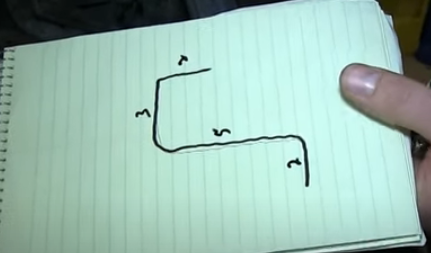

- Record the measurement of the brake line in inches before each bend

- Diagram the brake line on a piece of paper with the different measurements listed

- Add up the inches and cut off a little extra from the brake line

- Place the brake line in between the two wheels on the tubing cutter

- Tighten the tubing cutter

- Rotate the tubbing cutter until it feels loose

- Tighten the tubing cutter and repeat until the brake line is cut free

- Clean out the ends with the cutter on the tubing cutter

- Follow the diagram and mark the bends on the brake line. Lay measuring tape next to the brake line, and mark the spot of the first bend on the brake line with a marker. Slide the brake line down so the first mark is level with the end of the measuring tape. Mark the second bend on the brake line with a marker. Repeat these steps until all of the bends have been marked on the brake line

- Place the brake line into the slot on the bender tool that matches the brake line’s diameter.

- Place the first marked bend on the brake line at the 0 marker on the bender tool. The numbers on the tool represent the amount of degrees the brake line will be bent to. With the mark on the brake line lined up at zero, hold the brake bender steady and bend the brake line to 90 degrees, stopping the tool at the 90 mark. Repeat this for the remaining bends in the direction needed. If there is any excess brake line remaining, cut it off with the brake line cutter

Learn How to Replace Parts Yourself

1A Auto has tons of how-to, diagnostic, and general auto knowledge videos that can teach you all about specific makes and models or cars, trucks, and SUVs in general. Learn how to fix parts on your own car with step-by-step instructions and tips from professional mechanics.

Related Content

- Rear Drum Brakes Adjustment: How to Clean and Adjust Rear Drum Brakes

- Recycling Waste Fluids and Oils? How to Dispose of Motor Oil, Antifreeze, Brake Fluid, and More

- How to Bleed Brakes By Yourself

- Causes and Fixes of Pulsating Brakes

- Frozen Brakes: Do You Smell Burnt Rubber or Plastic?

- TRQ brake parts buying guide: Save time and money with quality brake kits

Shop Parts at 1A Auto

- Brakes & Wheel Bearing

- Brake Hoses, Lines, and Fittings

- Brake Master Cylinder

- Steering & Suspension

- Headlights & Lighting

- Brake Tools