Learn to Diagnose and Fix Low-Speed ABS Activation in Your Chevy Truck

One of the most common Chevy truck ABS brake problems is low-speed ABS activation. To find out why your Chevy truck has low-speed ABS activation, it’s best to first understand how the system works. The anti-lock braking system (ABS) is a safety feature that prevents your vehicle’s wheels from locking up when you suddenly press hard on the brake pedal. Locking up refers to when the wheels stop rotating, leaving the vehicle to slide forward due to the momentum.

In such a situation, the driver would not be able to effectively steer the car away from any objects that may be in front of him. The ABS system uses sensors to monitor the wheel’s rotational speed and a hydraulic unit to “pump the brakes”. This helps it know when to apply the brakes.

It repeatedly applies and releases the brake to prevent the wheel from locking up. Depending on the car you own, it could be connected to all four wheels or just the front wheel.

What Causes Low Speed ABS Activation?

Sometimes, the ABS system on your vehicle may activate unexpectedly when you brake at slow speeds of about 5-10 mph. This is despite putting a soft press on the brake pedal. You may hear the ABS pump groan from underneath and feel the brake pedal try to push itself back up against your foot. It goes from normal to soft then to rock solid in two to three seconds.

This is caused by a weak signal that’s generated by the ABS speed sensors due to corrosion. The rust that builds up on the steering knuckles pushes the sensors away from the toner and the axle. Since the signal is too weak, the ECU thinks that the car is undergoing abnormal deceleration and therefore, activates the ABS.

This is not just a common Chevy truck ABS brake problem but one of the most common problems experienced in 1999-2000 SUVs and trucks from General Motors. GM even has an existing product safety bulletin out. The bulletin acknowledges a condition in the cars that causes corrosion to occur between the wheel speed sensor and the front hub assembly.

In this post, we’ll take a look at how you can fix low speed abs activation in your car.

List of Tools Needed

- 18-22 mm sockets

- Breaker bar

- Ratchet and extension

- Needle nose pliers

- File

- Emery cloth

- Torque wrench

- Brake parts cleaner

- Bungee cord

- Floor jack

- Jack stands

- 6 mm Allen socket

- Paper towels

- Pick

- Rusty metal primer/spray paint

Steps on How to Fix This Common Chevy Truck ABS Brake Problem

Fortunately, this is one of the Chevy truck ABS brake problems that is pretty easy to resolve on your own. To fix the unnecessary pulsation or groan you feel and hear every time you step on the brake pedal at low speeds, you’ll need to clean off the corrosion that has built up around your ABS sensors.

How to Fix the ABS on Your Chevy Truck

- Remove the Wheels

You’ll need to first remove the center cap that covers the lug nuts on your wheels. The cap itself is held in place by plastic caps that you can quickly remove by hand or using a 21 mm socket. They come off together with the cap since they are attached.

Use a 22 mm socket and breaker bar to loosen the lug nuts while the vehicle is still on the ground. This prevents the wheel from turning on you. Once they are all loose, lift your car with a floor jack and support it using jack stands. Take all the lug nuts out and remove the wheel.

- Remove the Caliper and the Rotor

The ABS sensor in second-generation GM vehicles is mounted inside the steering knuckle. It sits inside the brake dust shield and brake rotor. You’ll need to remove both the caliper and rotor to access it.

Start by loosening the entire caliper using an 18 mm socket and breaker bar. You’ll want to remove the top and bottom mounting bolts and not the slide pins. You can turn the assembly towards the left to get more clearance.

Once the bolts are loose, use a ratchet to remove them entirely. Slide the caliper out of the assembly and use a bungee cord to wrap it around the wheel axle to prevent it from hanging loose.

Once that’s done, move to the rotor and pull it out. If you’re not able to slide it out easily, spray some rust penetrant in there. Set the rotor aside once it’s out.

- Remove the ABS Sensor

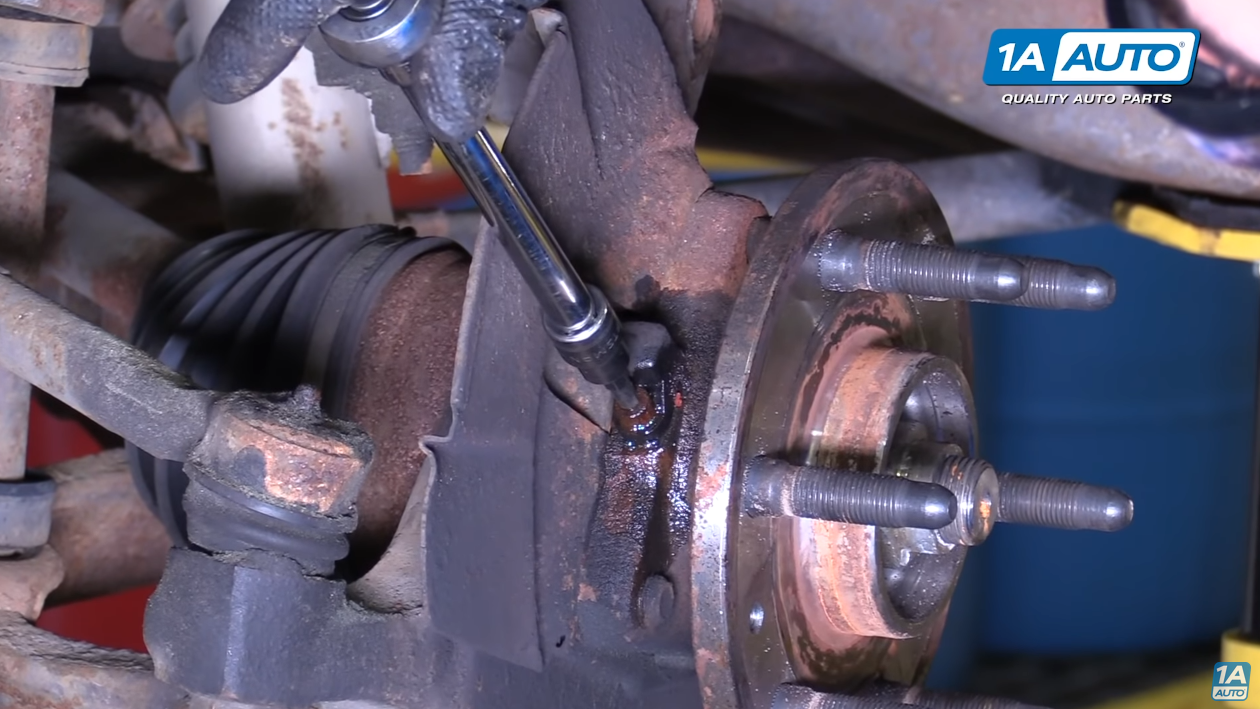

The ABS sensor is held in place by a 6 mm Allen bolt. You may find that the surface it sits on is corroded and dirty. The rust and dirt push the sensor away from the tone ring, causing low speed ABS activation.

Pick your 6 mm Allen socket and ratchet and carefully remove the bolt that secures the sensor. Put the bolt aside and wiggle the sensor out using your fingers. It should separate from the metal surface.

Take a pair of needle nose pliers and unclip the wire above that’s connected to the sensor. This allows you to completely remove the sensor out of the way. Be careful not to lose the small metal gasket that sits under the sensor.

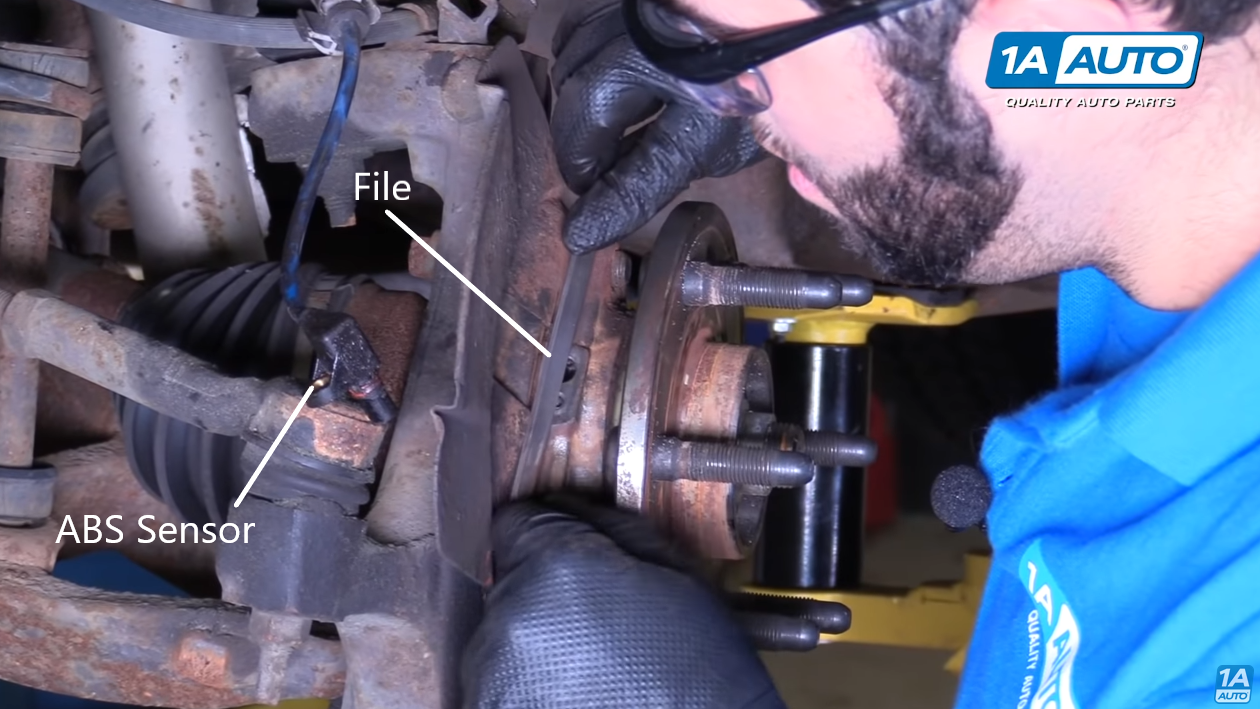

- Clean off the Rust and Dirt

Start by spraying some brake parts cleaner where the sensor sits. Wipe off all the dirt and grease using some paper towels. Use a piece of Emery cloth or a file to scrub off the rust as well. Make sure the file stays flat while using it. You do not want to put a gouge on the metal or leave the surface crooked or curved.

Once done, spray some more parts cleaner and wipe off any metal particles using paper towels. To make sure the surface stays protected from rust, apply a thin layer of rusty metal primer or spray paint.

Remember to clean the metal gasket that sits between the ABS sensor and the wheel hub assembly with a piece of Emery cloth. Do the cleaning on both sides and make sure the gasket stays flat.

Also, you’ll want to clean off any grease, metal particles, and dirt that’s on the ABS sensor using brake parts cleaner and paper towels. There’s a silicone sealer that’s located on the sensor. Use a pick to slide it out slightly to see if there’s any gunk or grease in there.

Confirm that the sensor is nice and flat and the plastic is not bent due to pressure from rust build up. If it’s bent, you’ll need to replace the sensor because it won’t make good contact with the tone ring.

- Reinstall the ABS Sensor, Rotor, and Caliper

Before screwing the ABS sensor back in place, ensure it’s entirely clean and that it has the metal gasket on. Remember to pass it through any opening that it came out from before pushing it down in. Tighten the Allen bolt just enough and clip the sensor wire back in place.

Slide the rotor back onto the wheel hub. You can clean off any grease prints you may have put on it using some brake parts cleaner. Undo the bungee cord that’s securing the brake caliper and re-install it onto the rotor. Torque the mounting bolts to 133 foot-pounds.

Once done, you can put back your wheel and tire and screw them in place using a ratchet. Torque them to 100 foot-pounds in a crisscross pattern when the vehicle is on the ground. Don’t forget to screw in the center cap.

- Repeat the Process on the Other Wheel

Since it’s not possible to identify which sensor was causing the ABS activation at slow speed, you’ll need to work on the other wheel as well. In Chevy trucks, there’s an ABS sensor located on each of the front wheels. All you need to do is follow the same steps as you work on the other wheel as well.

Preventing Future Chevy Truck ABS Brake Problems

Following these steps should prevent the unintended low-speed ABS activation on your Chevy truck. If the issue occurs again in the future, it may be necessary to perform steps again or make it an annual routine as a preventative measure.

Shop Parts and Tools Featured in This Article

Related Content

- Symptoms of a Bad ABS Speed Sensor

- How to Bleed Brakes By Yourself

- History of General Motors (GM)

- Common Problems on the 1994-04 Chevy S10

- Most Common GMC and Chevy Truck Problems