Sometimes fluids like oil can dry and break the protective sheath on wires over time. Wires can also melt and get damaged in other ways that leave them exposed and require them to be replaced before they cause problems with the part they are connected to. This post explains how to fix a broken wire that needs to be cut and replaced in a car by using a wire stripper and crimper tool, new wire, butt splices, heat shrinks, a lighter, electrical tape, and a wire loom.

How to Replace Chewed, Broken, Melted, Exposed, or Damaged Electrical Wires

Why Does My Car Have Broken Electrical Wires?

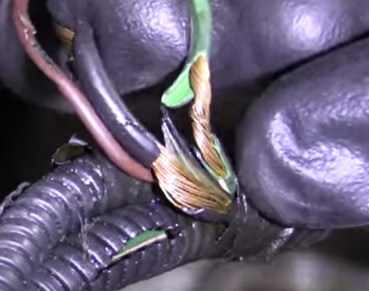

Sometimes the protective sheath on a wire can dry out and break off. Wires can also melt and tear for different reasons, like an animal that chewed through it. Once the copper wire is exposed, the wire will need to be replaced or it will cause functionality issues with the affected part.

For example, oil can leak onto wires and tape and dry them out over time, eventually causing cracking, brittleness, and breaking.

How to Replace a Broken Electrical Wire in 17 Steps

Items Needed

- Wire stripper and crimper tool

- New electrical wire

- Butt splices

- Heat shrinks

- Lighter

- Electrical tape

- Wire loom

Steps for How to Fix a Broken Wire

- Find New Wiring of the Same Gauge

Find wires of the same gauge as the faulty wire

- Pick a Section on the Damaged Wire to Cut

Trace the broken wires down to where they are flexible and not cracked or broken to find a good section to sever

- Strip the Ends of the New Wire

Take a piece of cut wire and strip the ends with a wire cutter to expose the copper wire

- Twist the Copper Wire

Twist the copper wire that is exposed

- Remove the Damaged Wire with Wire Cutters

Cut the section of the brittle, dry, melted, chewed, torn, or exposed wire off from the existing wire with wire cutters

- Strip the Ends of the Existing Wire

Strip the ends of the existing wire to expose the copper wire

- Twist a Butt Splice onto the Existing Wire

Twist a butt connector onto the existing wire as far as possible

- Crimp the Butt Connector to the Existing Wire

Crimp the center of the butt connector with wire stripper/crimper tool to secure the butt connector. Try to crimp the butt connector at the end of the wire sheath, right before the exposed copper wire.

- Test How Tight the Butt Connector Is

Tug the wire to confirm the butt connector is on tight

- Crimp the Replacement Wire to the Butt Connector

Repeat the steps above to connect the wires together by attaching the replacement wire to the butt splice

- Place a Heat Shrink Over the Repaired Wire

Place a heat shrink over the section of the repaired wire

- Melt the Heat Shrink

Melt the shrink with a lighter like a mini torch

- Place a Heat Shrink on the Other End of the Replacement Wire

For the outer end of the new replaceable wire, place the heat shrink on first before attaching the butt splice.

- Strip, Crimp, and Melt a Heat Shrink to the Ends of the Remaining Wires

Repeat the steps above to attach the other end of the replacement wire and to splice any new wires together

- Wrap the Wires with Electrical Tape

Once finished, wrap the wires with electrical tape

- Install a Wire Loom

Place a wire loom over the wires

- Tape the Wire Loom

Place tape over the wire loom

.

Related Content

- How to Splice Wires in a Car or Truck

- Relay is Bad in a Car, Truck, or SUV

- How to Replace a Headlight Socket

- How to Test a Fuse with a Multimeter

Shop Auto Parts at 1aauto.com